Antec LanBoy Air Modular Blue Mid Tower Case Review

Configuring the LanBoy Air

The LanBoy Air is a modular case and is designed to be reconfigured as the end user wishes. The manual that comes with the LanBoy Air states there are 34,800 different ways the LanBoy Air can be configured. Knowing that the end user would be adding/removing things from the frame Antec provides a small box to store the screws that are not being used.

At the very bottom of the front there is a small storage box. This box is also where the screws are stored for shipping. With a place to put the screws as they are removed we can start stripping the LanBoy Air to the frame.

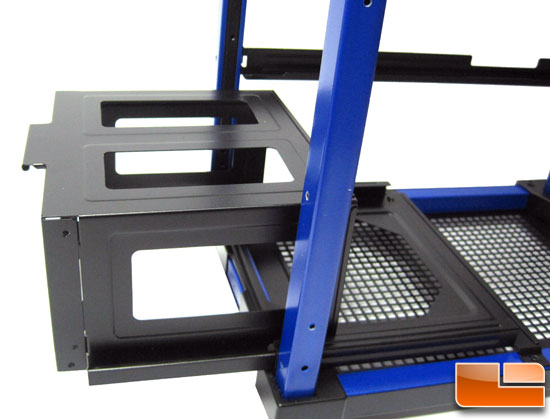

Lets say you dont like the stock arrangement with the power supply on the bottom, you want it in a more traditional top mount.

First, you pull off the rear panel.

Then, the motherboard tray and its support rails.

Same goes for the power supply cage and its support rail.

Put them back on in the new positions and in under 5 minutes you have the power supply in the top of the case.

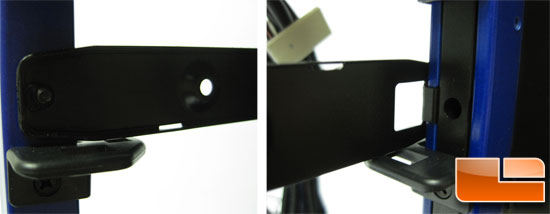

Dont like your optical drive facing front? You would rather have it facing the left?

No problem.

The rails that hold the 5.25 devices are bolted in on the front and have a clip on the rear. The frame has holes and slots that allow the drive to be turned. You can also move it up and down the frame at set intervals as well.

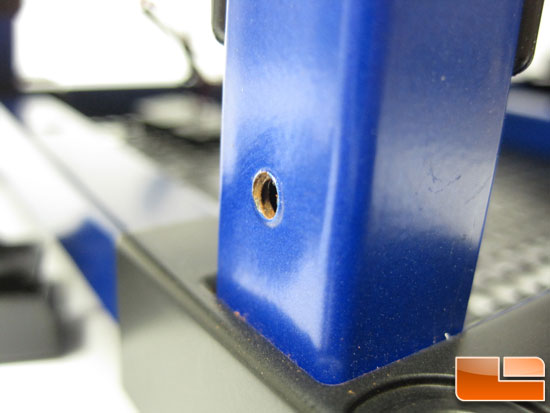

In removing some of the screws I noticed some were a little harder to remove than others. Looking closer at the holes I noticed there was rust. The frame is steel and there will be rust, but this is a new case. In 6 months to a year the little screws could be harder to get out. We contacted Antec and was told that the case that we received was one of the first made and that it sat around in Asia for a few months before being shipped out and that due to humidity in the region the freshly cut metal rusted where it was not painted. They suggested that we use some WD-40 to lubricate the screw holes and that only a limited number of cases should show rust like this. That makes sense as once these enter mass production and begin being sold they won’t have time to sit around and rust up like this.

Comments are closed.