Intel Beats AMD to Lead-Free Processors

Six Years In The Making – Lead Free Processors

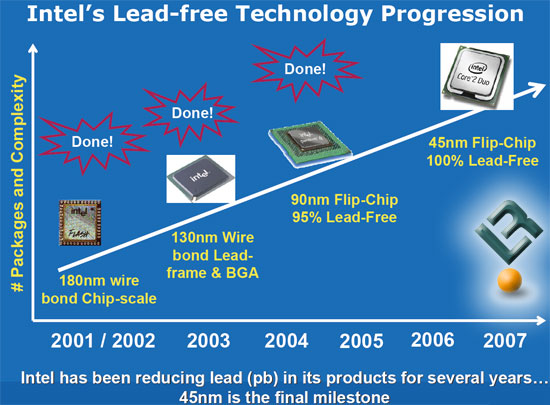

With next weeks launch of Intel’s 45nm family of microprocessors they will have official removed 100 percent of the lead (Pb) across its entire 45nm series of microprocessors. This is a huge milestone and it has taken Intel six years to strip the lead from the manufacturing process on their microprocessors! With the world so focused on ‘going green’ the move to a lead-free product could not have come at a better time.

Current 90nm and 65nm Intel desktop processors are 95% lead free and have been so for a few years now, but have had lead in the C4 bumps. Now that Intel has moved to 45nm Hi-k metal gate process technology they can transition to new lead-free materials on the bumps. This means that lead-tin solder is a thing of the past as tin-silver-copper solder can now do the job.

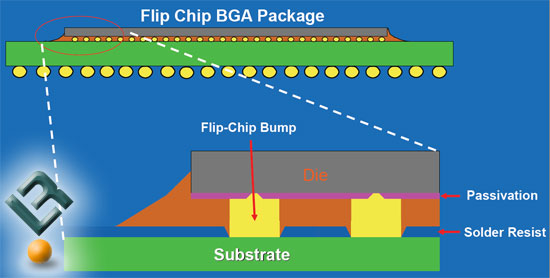

If you’re not familiar with what a ‘bump’ is and where the change is taking place, it’s under the integrated heat spreader (IHS) between the die and the substrate. Each and every flip-chip bump is now lead-free.

Now that the flip-chip bump solder points that used to contain lead have been replaced with a copper column and lead-free solder the processors are more environmentally friendly, but this does come at a cost. The melting point of lead-tin is 183C, whereas the melting point of lead-free solders is greater than 220C. This means increased stress on the flip-chip package and more power consumption since the convection ovens need their baking temperatures increased. To manage the increased stress and survive the higher process temperatures, Intel reengineered many parts of the processor. At the same time, the new solder alloy dramatically increases the current carrying capability of the electrical connection. Copper is a better conductor than the previously used lead/tin solder and it can connect to massive metal layers inside the die, so it’s actually better in this aspect. In the end using a little more energy to remove lead and having a better electrical connection, seems like the better choice for the environment.

The next time you buy or upgrade a computer system choosing a lead-free part is more than likely not a key feature that influences buying decisions, but if it is, you are now a better informed consumer. It should be pointed out that although 45nm processors are now 100% lead-free, Intel chipsets are not. Upcoming 65nm Intel Express chipsets will transition to being 100% lead-free in 2008, so we will still have to wait a bit for a 100% lead-free motherboard. Kudos to Intel for being the first to have a lead-free processor, but don’t stop! Keep going green across the board!

Legit Bottom Line: The new lead-free bumps is a step in the right direction; they can carry more current and enable higher performance microprocessors, is more reliable, and is better for the environment since it is 100 percent lead-free.

Comments are closed.