OCZ Fatal1ty 1000W Power Supply Review

Test Setup

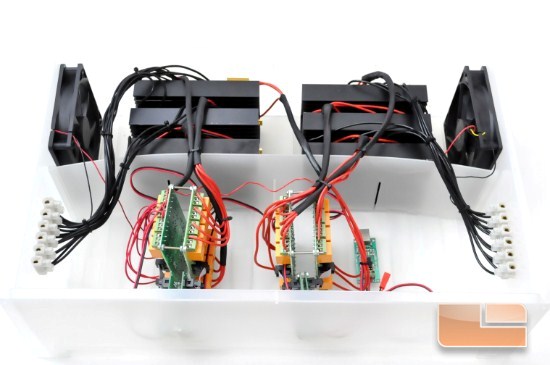

The load

In order to

be able to effectively and efficiently test any computer power supply unit, we

developed and constructed our own proprietary testing station. Our testing

station consists of a number of power resistors and small capacitors, which in

turn are connected to a RS485 electronic relay array which allow our load to be

controlled through computer software alone.

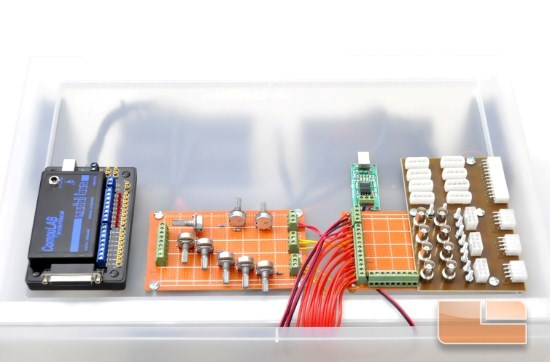

USB interface and

connection panel

When

accuracy and speed are of critical importance, a simple multimeter or voltage

meter is not sufficient for the task. To ensure the quality of our testing, an

USB laboratory interface is being used to continuously monitor and record the

readings of all voltage lines simultaneously. For ripple measurements, an

oscilloscope is necessary and we chose the USB Instruments Stingray, the most

widely used oscilloscope amongst low voltage PSU engineers and testers.

Measurement

instruments

For

accurate testing and repeatable results, a stable power input is also required.

Thus, we are providing power to our test samples through a 3kVA VARIAC which

allows us to control the input voltage of our test samples and also perform efficiency

tests under both 110V AC and 230V AC input. A Lutron DW-6091 is also being

used, monitoring the input voltage, real and apparent power, power factor and

amperage.

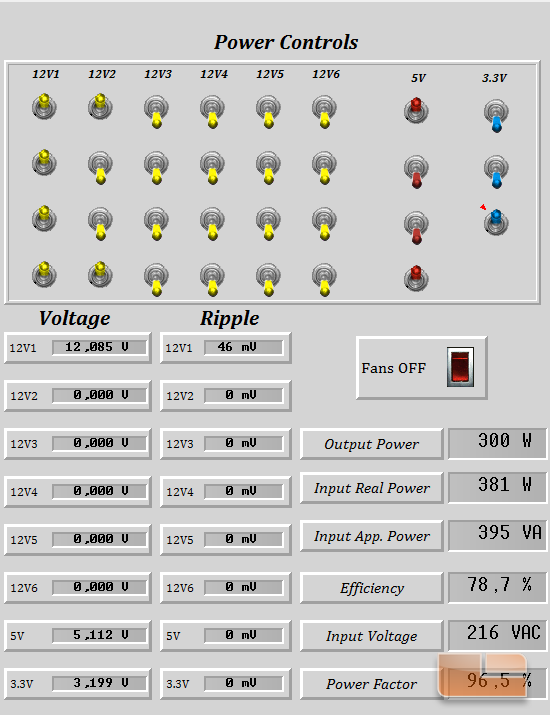

The software

A power supply testing procedure

would not be complete without thermal and acoustics tests. For our acoustics

tests we are using a SL-5868P digital sound level meter, placed 1 meter away

from the unit (DIN standard). Two PT100 sensors and their respective displays

are being used to monitor the ambient temperature and the exhaust temperature

of the unit.

Complete test setup

during trial run

Comments are closed.