Factory Tour – Kingston Technology Taiwan

Labeling FB-DIMM Server Modules

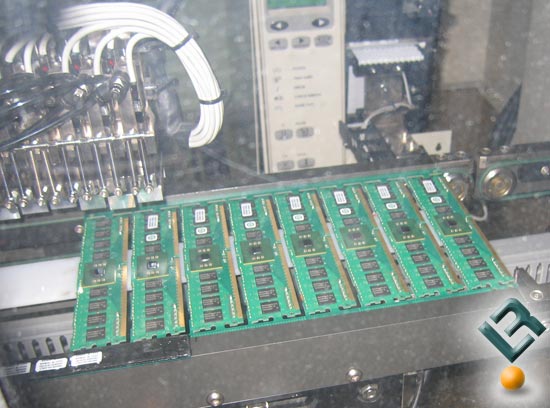

On the previous page we showed DDR2 Value RAM being made, but when we went over to labeling the assembly line was full of FB-DIMM memory modules! Here, we can see the machine placing on the part number and lead free stickers on a series of FB-DIMM modules. One would think that placing a sticker on an object would be simple, but check out the monitor on the labeling machine.

Since all memory modules are different the exact module specifications must be entered into the auto labeling machine to ensure the sticker is placed on the IC’s.

After being labeled, the modules go through another machine that will separate the PCB into individual DIMMs. The completed FB-DIMMs are then loaded into trays and carted for a move to the inspection/testing area.

Kingston continues the manufacturing process testing via the Agilent (formerly HP) 83000 High-Speed Testers, Advantest T5581H Testing Units that are observed in the front of the above picture. Kingston also tests memory on real platforms using proprietary software as well and that is what is in the background.

Taking a closer look at the rows of testing tables we find hundreds of systems that have memory being tested in them. Each monitor shows the status of four motherboards running on it and the status of the memory modules.

It turns out that the motherboards that were being used for testing were all ASUS P5WD2, which is a very common enthusiast board that uses Intel LGA775 processors. Once a module passes testing it is then packaged and is sent out the door headed for the distribution channel.

Comments are closed.